CONTRACT MANUFACTURING

SERVICES & CAPABILITIES

Richland Industries, LLC is a vertically integrated contract build-to-print metal fabricator. With 500,000 square feet under roof, 25 overhead cranes, and a dedicated railhead, Richland routinely builds both small and large complex fabrications. Working primarily with carbon steel, stainless steel, aluminum, and armor plate, Richland can cut, bend, break, weld, fit, machine, assemble, blast, and paint to demanding specifications.

Water Clarifier Rake Arm

Rake Arm for a clean water processing facility

Water Clarifier Rake Arm

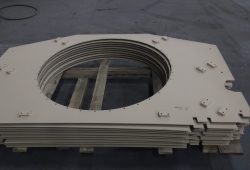

Rapid Prototype for Aerospace Industry

Rapid Prototype for Aerospace Industry

Mining Skip

Fabrication of a mining skip for a client in the mining industry for use extracting minerals such as salt, gold, and copper

Mining Skip

SERVICES

Richland Industries is certified to weld various metals.

- SMAW, GMAW, and GTAW.

- ASME Sec. IX and AWS

- Certified Welding Inspectors (CWI)

- Certified Welding Educator (CWE)

Welding

Richland Industries is a build-to-print metal fabricator.

- Fiber laser cutting

- Water jet cutting

- Plate and angle rollers

- CNC & manual press brakes

- 21 cranes of various sizes up to 25-ton capacity

Fabrication

Richland Industries has a fully equipped machine shop.

- 3-axis CNC milling machines

- 4-axis CNC milling machines

- CNC and manual lathes

- Overhead CNC vertical boring mill (Y-axis 30 feet)

Machining

Richland Industries has dedicated sand blasting facilities.

- 4,000+ square feet

- Blasting capacity from 185 to 750 cfm

Sand Blast

Richland Industries has multiple dedicated paint application resources.

- 7,500+ square feet for wet painting

- 10’x12’x25’ Powder coating booth

- 11’x12xx25’ Powder coating oven

Coating

Richland Industries can service small to medium carbon steel requirements from inventory or can acquire larger volumes of various metals as required. Stock includes plate, angle, and tube.